MENU

LNG

LNG

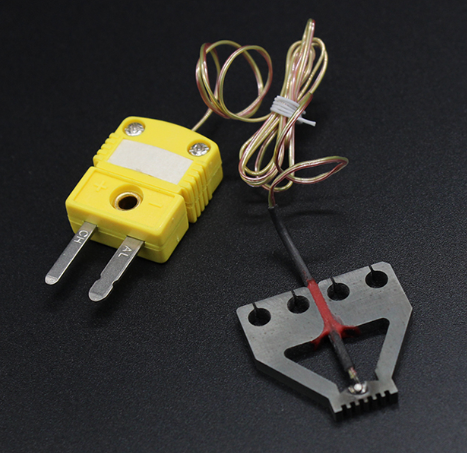

Spot welding heads can be divided into general and specialized types based on their purpose. The mold repair of traditional spot welding heads is completed by professional mold repair tools. Generally, welders in factories use sandpaper or files, but poor polishing and potholes can also affect the welding effect. From the commonly used welding head shapes, there are three types of shapes: pointed head, round head, and flat head, all of which are professional edge trimming tools. There are two types of edge trimming molds: 13 and 16 outer diameter, which are generally classified, so now all edge trimming molds are used; For specific information, click on the spot welding machine welding head grinding machine.

According to the specific situation, six materials can be used for spot welding heads:

1. Copper electrodes are suitable for spot welding of aluminum and aluminum alloys, as well as for spot welding of coated steel plates.

2. Chromium zirconium copper electrode is suitable for spot welding of carbon steel plate, stainless steel plate, galvanized plate and other parts.

3. Aluminum oxide copper electrodes are suitable for welding galvanized steel plates, aluminum products, carbon steel plates, stainless steel plates, nickel plates, brass and other parts.

4. Beryllium copper electrodes are suitable for carbon steel plates, stainless steel plates, galvanized plates, etc.

5. Tungsten copper electrodes are suitable for spot welding of copper, aluminum, and nickel.

6. Tungsten and molybdenum electrodes are suitable for welding copper alloys, especially for welding fine copper wires.

The spot welding head adopts the principle of double-sided double point overcurrent welding. During operation, two electrodes compress the workpiece to form a certain contact resistance between the two layers of metal under the pressure of the two electrodes. When the welding current flows from one electrode to another, instantaneous thermal welding is formed at two contact resistance points. The welding current flows from the other electrode along the two workpieces to form a circuit, without damaging the internal structure of the workpieces to be welded.

Pls contact with me if you need more details by email aria.diao@soucua.com.