MENU

LNG

LNG

Haba head has the characteristics of fast heating speed, small temperature error, wear resistance and high temperature resistance. We can design according to the customer's samples or drawings, or customize according to the customer's welding machine.

The molybdenum pulse hot press welding joint is made of high-quality molybdenum alloy. Low heat loss, wear resistance, corrosion resistance, high temperature resistance, non tin coating, etc. The titanium alloy hot pressing head is processed by CNC milling, precision grinding, CNC drilling, wire cutting, precision grinding, etc. The processed products have the characteristics of fast heating speed, small temperature error, wear resistance, high temperature resistance, corrosion resistance, and long service life. Advanced welding technology ensures that the solder joints are firm and do not fall off.

Model Description:

Method: HT-W (thickness) × L (length), W is 6MM, L is 60MM.

Used for FPC welding. We specialize in the production of welding heads, pulse welding nozzles, pulse hot pressing nozzles, pressure welding nozzles, convex spot welding nozzles, hot pressing nozzles, AVIO pressure welding heads, enameled wire spot welding heads, SMD spot welding heads, hot pressing flat wire welding heads, TC hot pressing welding heads, titanium alloy hot pressing heads, power inductance welding heads, micro spot welding heads, Baha heads, and high pressure welding heads. It can achieve various high difficulty irregular, precision, and universal parts processing, and produce micro welding electrodes (pulse hot pressing welding heads). The pulse hot press welding machine used is widely used for chip welding and flat wire welding of high and low frequency wound inductors.

Main applications:

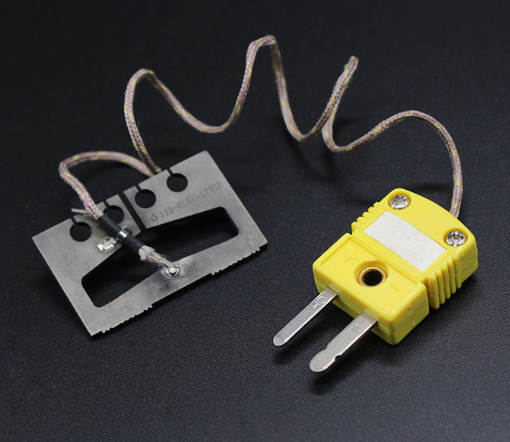

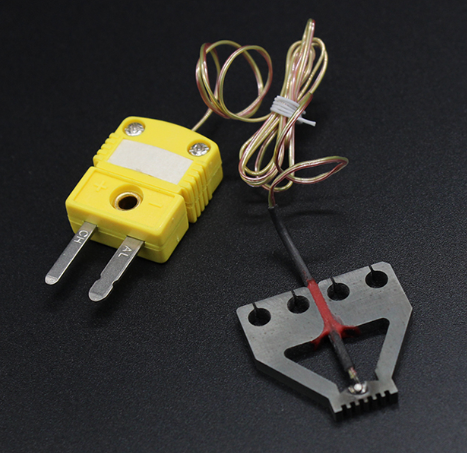

Corresponding to the main brand of pulse hot pressing welding machine, this product is a heating element for pulse welding. The temperature at the welding end is fed back by a thermocouple, and an appropriate current is applied to both ends of the welding head to obtain the appropriate temperature. Heat is transmitted to the workpiece to be bonded through the bottom of the welding head, ultimately welding the welded parts together. This welding method has minimal thermal impact on surrounding devices.

Mainly used for welding PCB substrates, FPC and FFC, ACF connection of LCD and TCP, direct connection of various coil insulation enamel and terminals, heating and bonding of plastics, etc. By using this welding method, there will be no false soldering phenomenon and multiple welding points can be achieved at once to ensure welding quality.

Pls contact with me if you need more details by email aria.diao@soucua.com.