MENU

LNG

LNG

The insiders in the industry should know that the jig sheet of the winding machine is the basis for the numerical control winding machine to conduct winding, and the jig sheet of the winding machine is the bridge between the winding machine and the user's requirements for the coil. Both the purchaser and the operator of the winding machine must understand that the winding machine can do nothing without the clamping piece of the winding machine that has been strictly designed and processed. Therefore, the technical content of a winding machine manufacturing enterprise is not always measured by how well the winding machine is made and how beautiful the appearance is. These are imaginary. In fact, for users, a winding machine capable of winding qualified products is what they need most.

The jig pieces of the winding machine can be divided into the types with or without skeleton according to the different coils of the user; According to the different shapes, it can be roughly divided into square, round, etc; According to different functions, it can be divided into general type, special type, combined adjustable type, etc. When the winding machine is working, the basic principle of coil positioning is to reasonably select the positioning reference and clamping plan. A complete winding machine clamp sheet should include the following parts:

Positioning parts: positioning parts are used to ensure that the coil is in the correct position in the fixture. Generally, post pins, bolts and thimbles are used to position both sides of the coil and the inner plane. The design of positioning parts should ensure that the slot type of the coil is unchanged during winding, and facilitate subsequent operations such as demoulding and tape wrapping.

Clamping equipment: similar to the function of positioning parts, the function of the clamping equipment is to press and clamp the clamp firmly, so that the clamp can still maintain the correct concentricity when subjected to external forces (such as the pull of thicker wire on the spindle) during the high-speed swing of the winding machine spindle, so as to ensure that the clamp does not have too much runout, thus affecting the winding quality.

The clamp details are the basic parts of the winding machine clamp sheet. Positioning parts, clamping equipment, guiding equipment, various connecting equipment, etc. are all installed on it. Therefore, the clamp details are generally more complex, which ensures the relative orientation accuracy between the components, and its own accuracy requirements are relatively high.

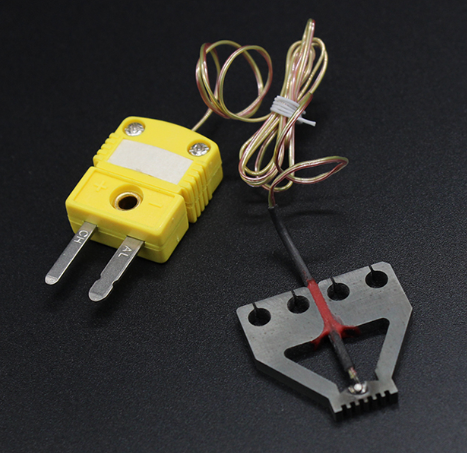

Other equipment or components. It refers to the equipment or parts set by the user for special needs of the winding machine clamp, such as adding power equipment or external NC induction probe number. In order to improve the power of the CNC winding machine, the following points should be paid attention to when establishing the positioning benchmark and clamping plan of the clamp when designing the clamping piece of the winding machine for customers.

In order to facilitate the filing of the company's overall handling documents, reduce the design time and facilitate processing, the design basis, process basis and programming and accounting basis shall be consistent. In order to improve the winding power for customers, future operations should be considered as much as possible during the design, the clamping process of the fixture should be reduced, and manual adjustment should be reduced as much as possible to avoid affecting the useful working time of the CNC winding machine. Try our best to design clamps that can coil qualified products for customers in a convenient way and with relatively simple ideas, and try our best to coil qualified products after one positioning and clamping.

The function of the winding machine clamp is to clamp the coil. It is necessary to ensure the reliable clamping of the coil and improve the positioning accuracy, so as to facilitate the loading and unloading and improve the processing efficiency. The components of the winding machine clamp sheet shall not hinder the normal operation of the winding machine, and the concentricity and component of the clamp shall not cause too much burden on the moving parts of the winding machine.