MENU

LNG

LNG

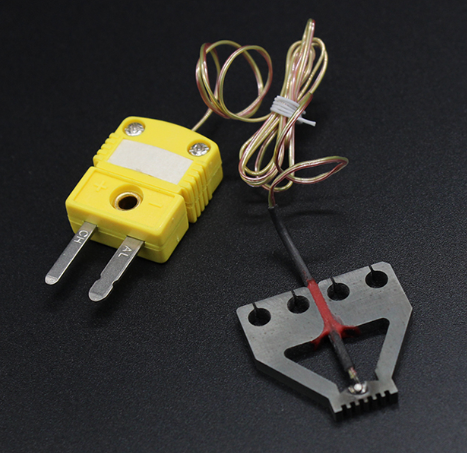

A spot welding head is a device used in resistance welding equipment that is in direct contact with the object to be welded and directly supplies current and pressure to the object to be welded. There are many kinds of spot welding heads, including butt welding heads and micro spot welding heads.

Butt spot welding heads

Is it divided into upper and lower parts. When welding, the welded object is located in the center of the upper and lower parts. Current passes through the welded object and generates heat on the welded object, Sometimes heat occurs primarily through the contact surface of the welded object and the welding head. This depends on which part of the current loop has a large resistance.

Micro spot welding head

The micro spot welding head is the welding head corresponding to the microelectronic spot welding machine. Its characteristic is that the welding head and the welding machine have now formed a loop. After the current passes through this loop, the heat is generated at the high end of the welding head. The welding head actively generates heat, while the welded object does not actively generate heat.

When the welding head in the spot welding equipment welds thinner metal wires, it is required to press the welding head on the two welded metal wires, and the welded metal wires are welded together through the effect of the high temperature welding head. In the process of winding the coil by the numerical control winding machine, manual welding is always used when the welding head welds the coil wires. However, because the welding head is easy to wear and accumulate foreign matter, the welding head needs to be cleaned, therefore, the welding power is low and the welding quality is unstable, which seriously affects the production power and coil quality of the winding coil of the CNC winding machine.

Spot welding heads include chromium zirconium copper ,alumina copper, beryllium copper, tungsten copper, etc. They are selected according to different products and materials for different jobs. For example, chromium zirconium copper spot welding heads are generally equipped with this material. It can spot welding cold and hot steel plates and stainless steel plates. For example, beryllium copper spot welding heads can be selected under the condition of high power of spot welding machines; Alumina copper spot welding heads are generally welded to galvanized sheets, because the chemical substance and hardness inside are more suitable for galvanized sheets, but other welding parts have high hardness and affect its conductivity.