MENU

LNG

LNG

Tungsten spot welding heads are widely used in modern technology in pure metal state and alloy state. The main alloy states are alloy steel, tungsten carbide-based cemented carbide, wear- resistant alloy and strong heat alloy. Tungsten is mainly used in the following industrial fields:

Iron industry

Tungsten is mostly used in the production of special steel. The high-speed steel used in large quantities contains 9%-24% tungsten, 3.8%-4.6% chromium, 1%-5% vanadium, 4%-7% cobalt, and 0.7&-1.5% carbon. The characteristic of high-speed steel is that it can be automatically quenched at high tempering temperature high hardness and wear resistance until 600-650℃. Tungsten steel in alloy tool steel contains 0.8%-1.2% tungsten; chromium tungsten silicon steel contains 2%-2.7% tungsten; chromium tungsten steel contains 2%-9% tungsten; chromium tungsten manganese steel contains 0.5%-1.6% tungsten. Tungsten- containing steel is used to manufacture various tools: such as drill bit, milling cutters, drawing dies, female and male dies, air support tools and other parts. Tungsten magnet steel is a permanent magnet steel containing 5.2%-6.2% tungsten, 0.68%-0.78% carbon, and 0.3%-0.5% chromium. Tungsten-cobalt magnetic steel contains hard magnetic materials of 11.5%-14.5% tungsten, 5.5%-6.5% molybdenum, and 11.5%-12.5% cobalt. They have high magnetization and coercivity.

Tungsten carbide-based cemented carbide

Tungsten carbide has high hardness, wear resistance and refractory properties. These alloys contain 85%-95% tungsten carbide and 5%-14% cobalt. Cobalt is used as a binder metal, which gives the alloy a certain strength. Some alloy mainly used for processing steel also contain carbides of titanium, tantalum and niobium. All these alloys are manufactured by powder metallurgy. When heated to 1000-1100℃, they still have high hardness and wear resistance.

The cutting speed of cemented carbide tools far exceeds the cutting speed of tool steel tools. Cemented carbide is mainly used for cutting tools, mining tools and wire drawing dies.

Heat-strength and wear-resistant alloy

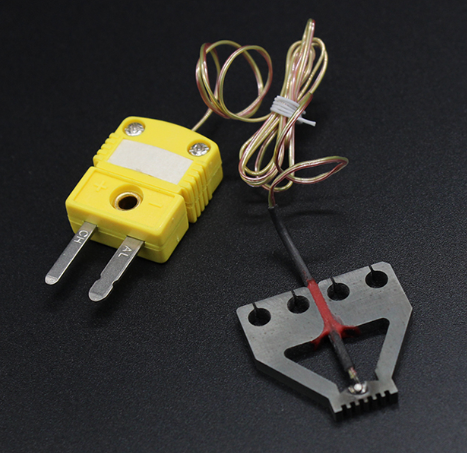

As a refractory metal, tungsten is a component of many heat-strength alloys such as 3%-15% tungsten, 25%-35% chromium, 45%-65% cobalt, 0.5%-0.75% carbon and other constituent parts of spot welding heads, such as aero engine valves, working parts of mold thermal cutting machines, turbine wheels, excavating equipment, and outer surface coatings of plowshares.

In aviation rocket technology and other sectors that require high thermal strength of mechanical parts, launchers and some instruments, alloys of tungsten and other refractory metals (such as tantalum, niobium, molybdenum, rhenium) are used as thermal strength materials.