- When the new evaporation boat is used, the voltage is gradually increased by screen operation to control the time, each time the voltage is increased for 5 minutes, and them it is increased again( for example 7V-8V-9V)or started according to the program set by the aluminum plating machine. Gradually boost and heat the evaporation boat process anneal to release internal pressure. At the same time, the gas absorbed inside the boat material is also released. Aluminum wire combines with the evaporation boat, and it takes about 20 minutes to wet it. Wetting too fast will reduce the stability of the evaporation gas and greatly shorten the service life of the evaporation boat.

- The longer the operation time, the hotter the evaporation boat voltage must be kept decreasing( depending on the splash phenomenon).When the voltage is reduced, pay attention to reducing the feed rate by aluminum wire. At the beginning of continuous production, the voltage of the evaporation boat at the end of roll transpiration is lower than that at beginning of evaporation. The time required to lower the voltage of the high resistance evaporation boat(650COM) is longer than that of the low resistance evaporation boat. The resistance of almost all substances will change with the change of temperature. Generally, when the temperature rises, its resistance will also increase. The high temperature resistivity applied and fixed during the design of the evaporation boat, which matches the evaporation power supply.( High temperature resistivity is thousands of times that of room temperature resistivity).

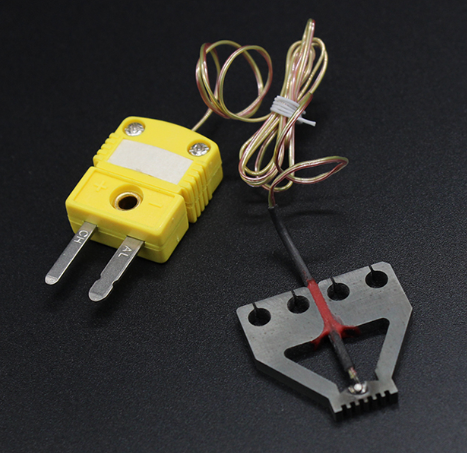

- After using the evaporation boat, use a brush to quietly clean the aluminum slag on the appearance of the boat, and use wire brush cleaning brush every time in the future. Every time the cleaning work is finished, check the evaporation boat to ensure that it is clamped, otherwise it will jump when it starts. When starting the evaporation boat, but one of them is not lit, do not continue to send aluminum wire arc until it is lit. The aluminum wire should be adjusted to approach the evaporation boat forward first, and them the evaporation boat should be initiated to ignite it. Otherwise, it will not only damage the fixture, but also damage the evaporation boat and shorten the life of the evaporation boat.

4.The evaporation boat with relatively large aluminum attachment surface has a wider transpiration scale, the evaporation coating is easy to control and the time for continuous transpiration is longer. If the transpiration intensity is too high, the transpiration rate will increase, but the Transpiration method is more vertical to the film direction evaporation.(Every time the transpiration temperature increase by 75℃,the transpiration rate of aluminum will be about doubled) when the working temperature rises, the corrosion rate of ceramic materials will be doubled, and the smaller transpiration angle will make the transverse uniformity of the coating worse. As well as the cleaning steps after each roll of evaporation is completed, the liquid aluminum should be carefully increased to cover the contact surface as much as possible.

LNG

LNG