MENU

LNG

LNG

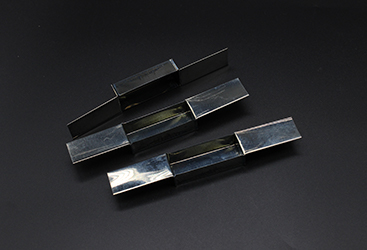

Density: ≥10.2g/cm^3

Model: 361,364, MO1, TZM, MLa

Standard: ASTM B386-91, GB/T3876-83

Purity: ≥99.95%

Process: hot rolling, cold rolling, alkaline washing, shearing, riveting

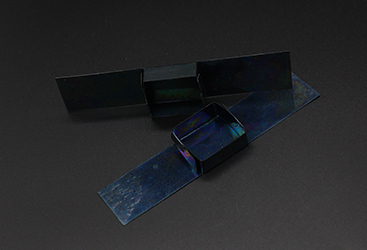

Molybdenum boat high melting point(2610°C)/ Tungsten boat high melting point(3410°C)

Low thermal expansion rate, high thermal conductivity, low vapor pressure, excellent resistance to metal melting and good glass corrosion resistance

| Main features | Thermodynamics | Electrical property | Optical property |

|---|---|---|---|

| Mo Element symbol: Mo | Melting point: 2610°C | Conductivity: 34% IACS at 0°C | Reflectance: 46% at 500 nm, 93% at 10,000 nm |

| 42 Atomic number: 42 | Boiling point: 5560°C | Resistivity: 53.4 nΩ·m at 20°C | Color: silver white |

| 95.94 Atomic weight: 95.94 | Specific heat: 0.276 kJ/kg x K at 20°C | Thermo Electromotive force: 1.45 mV (compared with platinum), 0 to 100°C | |

| Density: 10.22 g/cc at 20°C | Latent heat of fusion: 270 kJ/kg (estimated value) | Electro-chemical equivalent: valence 6, 0.1658 mg/C | |

| Compression ratio: 36 micron 2/N at 293°C | Thermal conductivity: 142 W/mx K at 20°C | ||

| Heat of combustion: 7.58 MJ/kg Mo |

Customized specifications: according to the size provided by the customer

Material: MO-1 or Mo-based alloy.

Density: 10.15-10.2 g/cm3.

Production method: the sheet is rolled.

Adaptation temperature: It can be used under 1400℃-1900℃

1. Applications in the field of touch screens: mobile phones, computers, MP4 and other digital product screens, etc.

2. Application in the field of information display: LCD screens, various LCD screens, plasma screens, etc.

3. Application in the field of coated glass: telescope lens, spectacle lens, decorative glass, etc.

4. Applications in the field of information storage: magnetic information storage, magneto-optical information storage, etc.

5. Application in decorative accessories: coating of watch cases, spectacle frames, hardware, small accessories, etc.