MENU

LNG

LNG

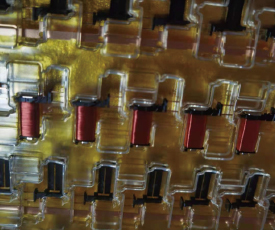

Temperature sensing wire type: E type, K type, J type, T type (optional)

Length of temperature sensing wire: 200-1000MM/piece (optional)

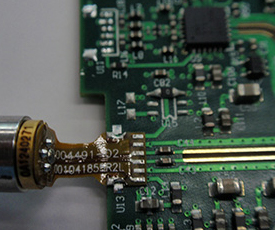

Welding head material: molybdenum / titanium / tungsten alloy, etc

Service life: 50000-1000000 times

Delivery time: shipped within 1-3 days

1.MCU temperature control——Synchronize with imported welding machine system

2.Chinese and English interface——Meet domestic and export demand

3.Independent research and development, with software copyright——Modify the program at any time to interface with the automata

4.Precise, accurate and stable temperature control, temperature difference±1°——Thermometer synchronously detects temperature curve

5.small volume——Place the assembly line to save space

6.More Professional——Juke has two design technologies: hot-press welding machine and hot-press welding head

7.Customized hot press welding head 1-3 days delivery——Own slow wire processing, no need to send out

1.MCU temperature control——Synchronize with imported welding machine system

2.Chinese and English interface——Meet domestic and export demand

3.Independent research and development, with software copyright——Modify the program at any time to interface with the automata

4.Precise, accurate and stable temperature control, temperature difference±1°——Thermometer synchronously detects temperature curve

5.small volume——Place the assembly line to save space

6.More Professional——Juke has two design technologies: hot-press welding machine and hot-press welding head

7.Customized hot press welding head 1-3 days delivery——Own slow wire processing, no need to send out