MENU

LNG

LNG

LNG

LNG

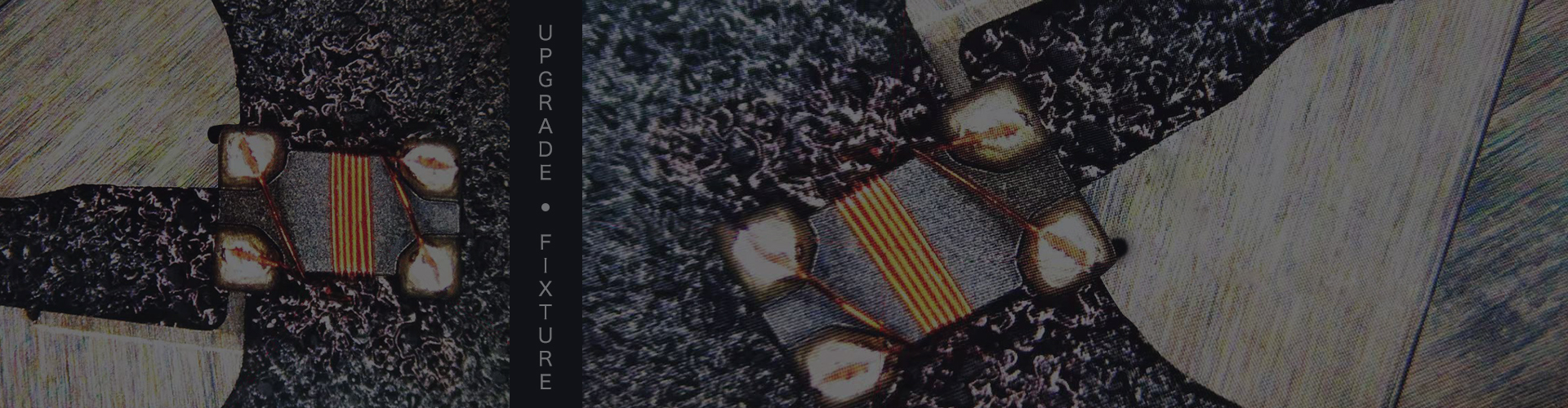

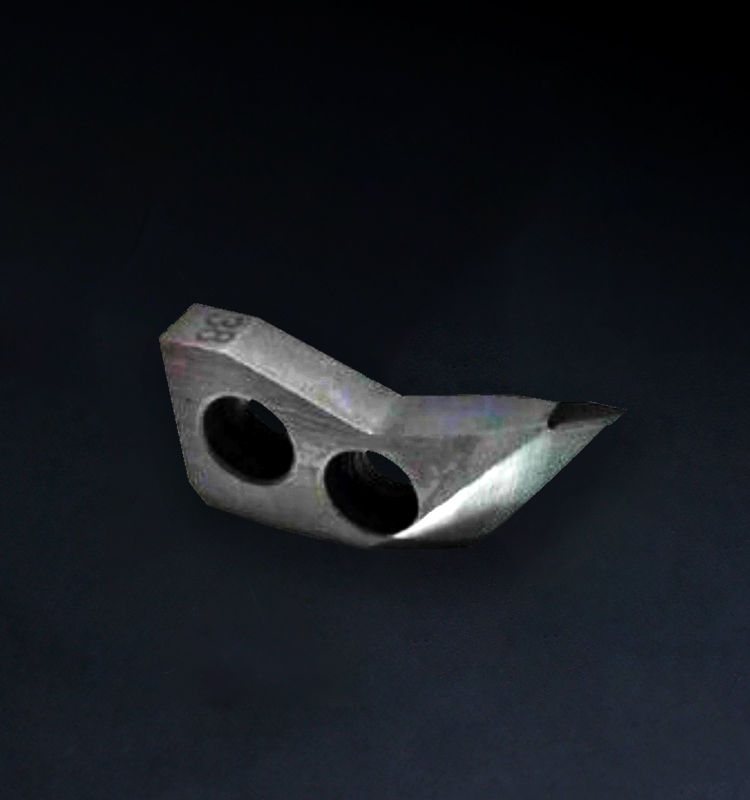

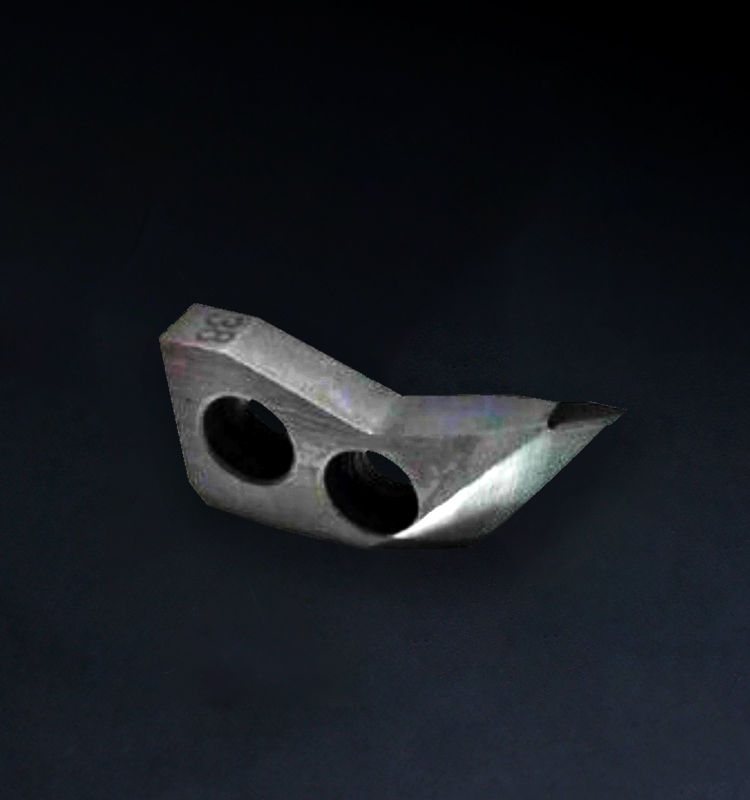

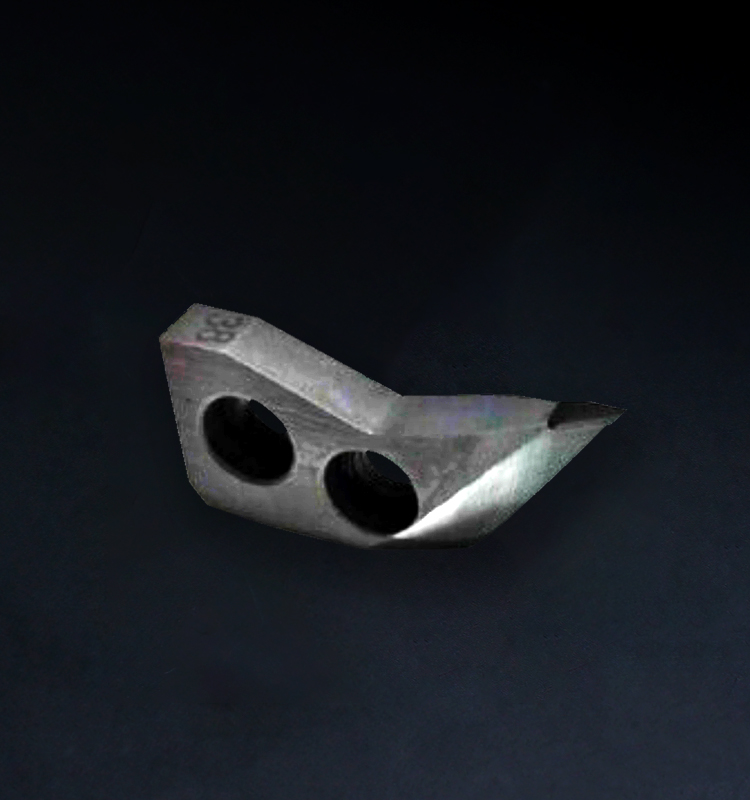

PCD grooving cutter is also called diamond grooving cutter and grooving cutter. The tool angles are 30°, 35°, 40°, 45°, 50°, 55°, 60°, 65°, 70°, 75°, 80°, and 90°.

Uses of PCD grooving: PCD grooving cutters are mainly used for grooving guide wheels and rollers in the photovoltaic industry. Their service life is much longer than that of traditional alloy tools. Generally, the normal service life is 26-40 hours! The grooving quality is very high, the groove shape is stable, and the angle is good! The groove side has good roughness, no burrs, and can be used continuously. It helps you solve the grooving problems of the guide wheel, contact wheel, main roller of the squarer, directional wheel, guide wheel, contact wheel and other parts! Increase your production efficiency by at least 5 times and reduce product scrap to zero! It is the most precise grooving knife in the world today!

The PCD grooving cutter produced by Dongguan Soucua Precision uses synthetic polycrystalline diamond (PCD) material as the cutter head material, which is suitable for PCD grooving. It adopts precision silver brazing process, and the cutting edge and groove are uniform. After fine special treatment and sharpening and shaping by Swiss precision PCD precision grinder, your use will be sharp and precise!

Language

Language

Mailbox:brian.he@soucua.com

Mailbox:danny.ng@soucua.com

Mailbox:rose.zhang@soucua.com

Mailbox:smion.siew@soucua.com

Mailbox:mila.lin@soucua.com

Postcode:523300

Address:No. 11, Hengjiao Hengling Street, Hengjiao Village, Shijie Town, Dongguan City, Guangdong Province, China

Copyright ©2020Dongguan Soucua Hardware Electronics Co., Ltd.

All Rights Reserved