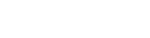

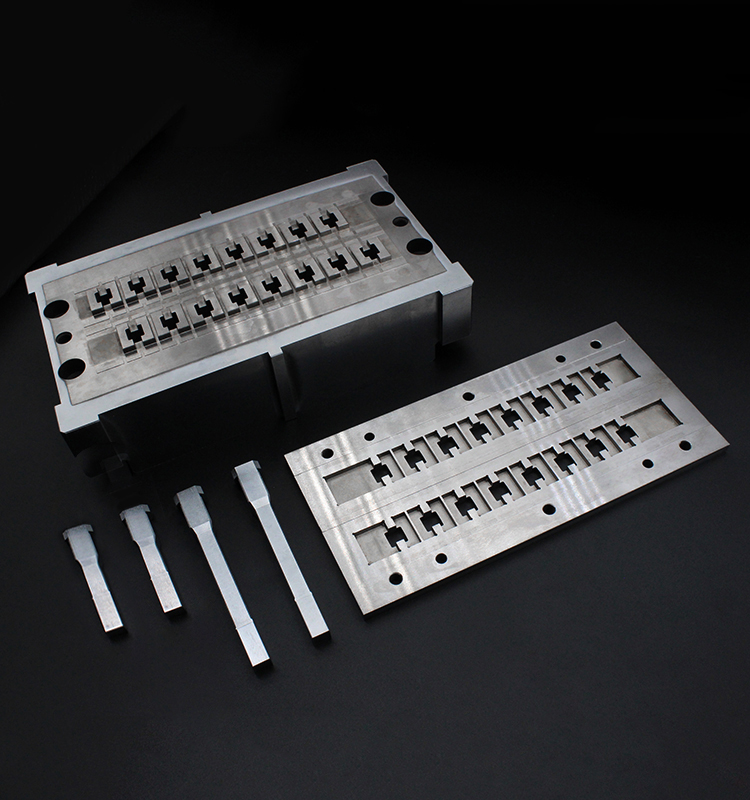

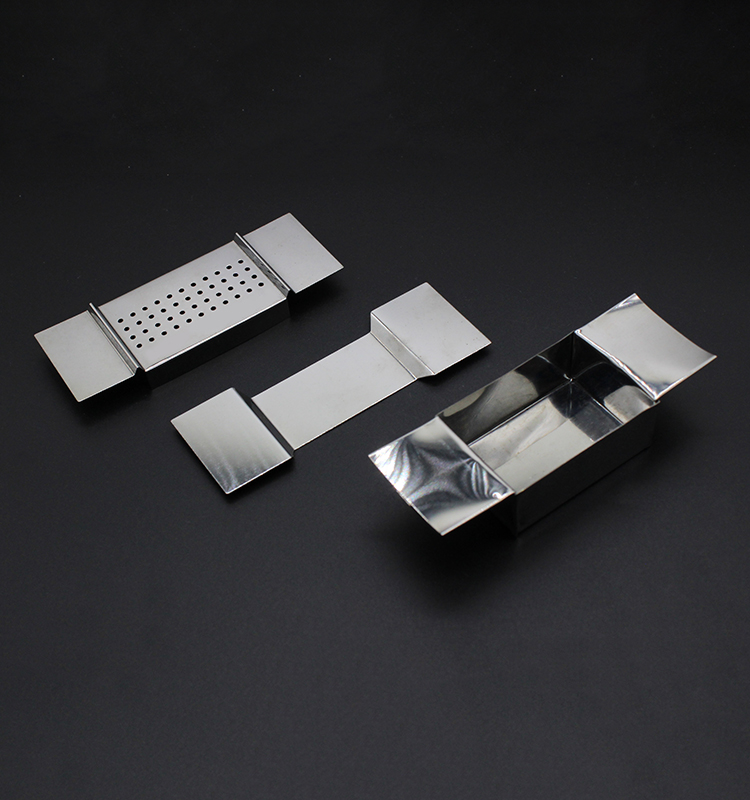

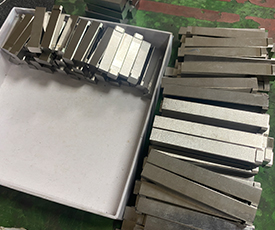

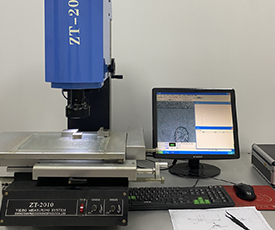

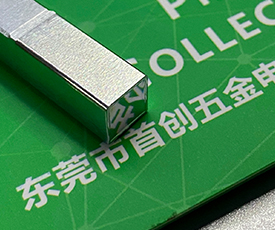

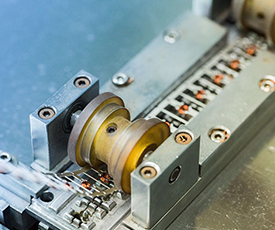

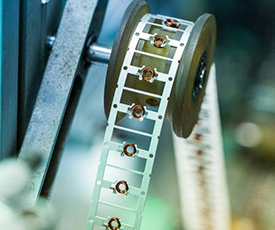

5 experienced engineers, more than 10 years of engineering design experience; 10 technicians, more than 8 years of production and processing experience, which can meet the personalized needs of customers and ensure the accuracy and quality of precision parts; Quality inspection team, full-scale 100% inspection to ensure that products meet customer requirements.

MENU

LNG

LNG