MENU

LNG

LNG

Power: 1000W-4000W optional;

The microcomputer version CPU accurately controls the temperature and local instantaneous heating, which can well inhibit the thermal impact on the surrounding components

Real time display of temperature curve during welding, closed-loop online feedback control of thermocouple and accurate feedback of welding head temperature;

1-4 temperature rise sections can be set, and the temperature rise time and temperature can be set freely, which is accurate, rapid and stable;

20 welding procedures can be stored to meet the welding needs of different products;

The whole welding process is completed in 1-6 seconds, and the special welding head is customized according to the product;

Small size, equipped with a variety of interface modes, which can realize robot or fully automatic unmanned welding;

Long service life of welding head to create value for customers;

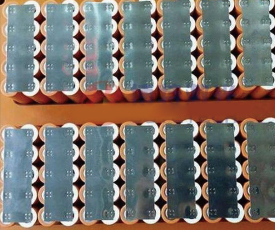

Multiple solder joints are completed at one time, with high efficiency, good consistency, high welding strength, beautiful solder joints and simple operation;

Capacity: 350 pieces / hour for ordinary models and 400-1000 pieces / hour for semi-automatic and full-automatic models.

1. Single-chip microcomputer temperature control;-synchronized with imported welding machine system

2. Chinese and English interface;-Language is not a problem

3. Independent research and development, with software copyright;——Revise the program at any time to connect with the automaton

4. Accurate and stable temperature control, temperature difference ±1°;——Thermometer synchronously detects temperature curve

5. small volume;——Place the assembly line to save space

6. More Professional;——Has 8 patented technologies for welding machine and welding head

7. Customized hot-pressing welding head can be shipped on the same day as soon as possible;-complete equipment, no need for external processing

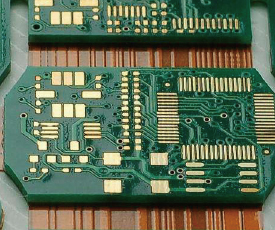

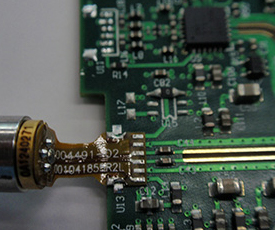

1. Welding very fine coaxial wire Welding of I-PEX, FPC, FFC and PCB

2. ACF connection between LCD and TCP

3. Welding of USB connectors such as HDMI and MINI

4. Direct connection between Teflon wire and terminal

5. Heating bonding of plastic plastics, etc.